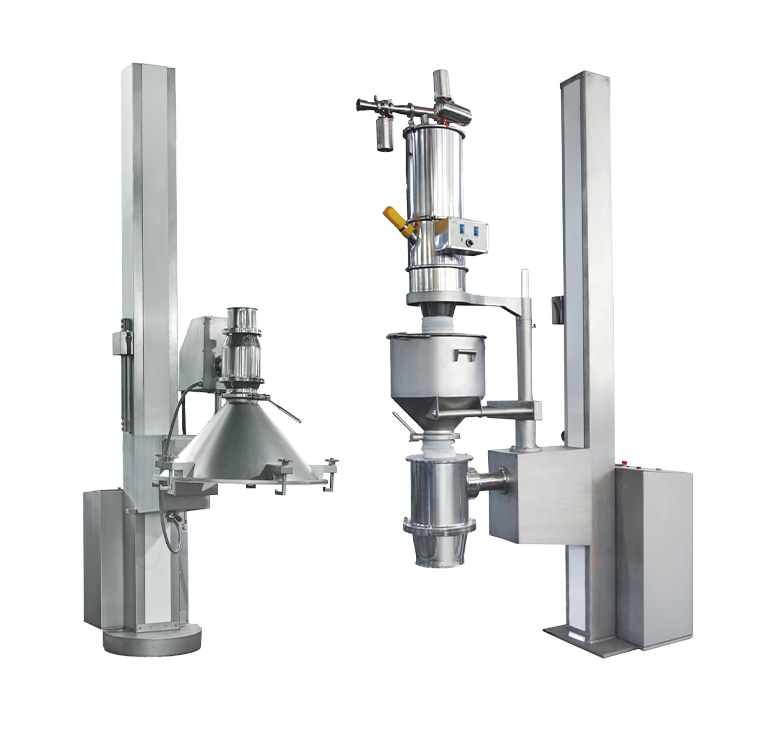

Unload the tipper with dock it with fluid-bed material container; lock the cone adpaper and rasie it up to the requied height which allows the bin moving down; lower down the tipper and cone adpater and dock it with bin, open the butterfly valve on the adpater unloading the material from the cone adapter, the dry on-line cone mill starts runing for dry sizing. The dry sized product flow down into the IBC bin. Upon finishing the operation, un-docking each parts to be ready for next processing and operation.